Rotary Screw Compressors

Advanced Ceccato Rotary Screw Compressors featuring variable speed drive technology and ES4000 intelligent controller.

Delivers up to 1,035 l/min FAD with ultra-quiet operation at 57 dB(A).

Perfect for Australian workshops requiring reliable compressed air for automotive, manufacturing, and industrial applications.

Available in base and tank configurations with energy-efficient performance.

Brochure: CSM 3-10 HP

Brochure: CSM 7.5-20 HP

Description

Description

Rotary Screw Compressors: The Ultimate Workshop Solution for Australian Professionals

When Australian workshops demand the ultimate compressed air solution combining power, efficiency, and reliability, rotary screw compressors stand as the definitive choice for professional operations. The Ceccato CSM 3-9 HP IVR range represents the pinnacle of rotary screw compressors technology, delivering unmatched performance that transforms workshop productivity across automotive, manufacturing, and industrial applications.

Advanced Technology in Rotary Screw Compressors

Rotary screw compressors incorporate revolutionary variable speed drive technology that sets new standards for workshop compressed air equipment. Unlike conventional compressors that operate at fixed speeds, these advanced rotary screw compressors intelligently adjust power output to match demand, delivering optimal efficiency whilst significantly reducing energy consumption and operational costs.

The sophisticated ES4000 controller represents the technological heart of these rotary screw compressors, providing intuitive management and unparalleled precision in compressed air delivery. This intelligent controller ensures rotary screw compressors operate at peak efficiency, automatically optimising performance parameters to deliver consistent, reliable air supply for demanding workshop applications.

Superior Workshop Performance

Rotary screw compressors deliver exceptional performance metrics that make them the ideal workshop choice for Australian professionals. With air delivery capacity reaching up to 1,035 litres per minute FAD, these rotary screw compressors ensure reliable air supply for multiple simultaneous applications including pneumatic tools, spray painting, tyre changing, and diagnostic equipment operation.

The rotary screw compressors operate at remarkably low noise levels, achieving sound levels as low as 57 dB(A) through advanced engineering and precision manufacturing. This quiet operation makes rotary screw compressors perfect for workshop environments where noise reduction is essential for productivity and worker comfort.

Energy Efficiency and Cost Savings

Rotary screw compressors incorporate variable speed technology that revolutionises workshop energy management. By automatically adjusting power usage to match compressed air demand, these rotary screw compressors significantly reduce energy costs compared to conventional fixed-speed compressors, providing rapid return on investment for workshop operations.

The intelligent design of rotary screw compressors optimises air production efficiency, eliminating energy waste during low-demand periods whilst maintaining instant response capability when full capacity is required. Australian workshops benefit from substantial electricity cost reductions whilst maintaining superior compressed air performance.

Versatile Workshop Applications

Rotary screw compressors prove invaluable across diverse workshop applications throughout South Australia, Northern Territory, and Western Australia. Automotive workshops rely on these rotary screw compressors for consistent air supply supporting tyre service equipment, pneumatic tools, spray booths, and diagnostic systems requiring reliable, clean compressed air.

Manufacturing facilities benefit from rotary screw compressors ability to support automated production lines, quality control processes, and precision assembly operations. The consistent pressure delivery and reliability of rotary screw compressors ensures uninterrupted production and maintains quality standards across demanding industrial applications.

Flexible Configuration Options

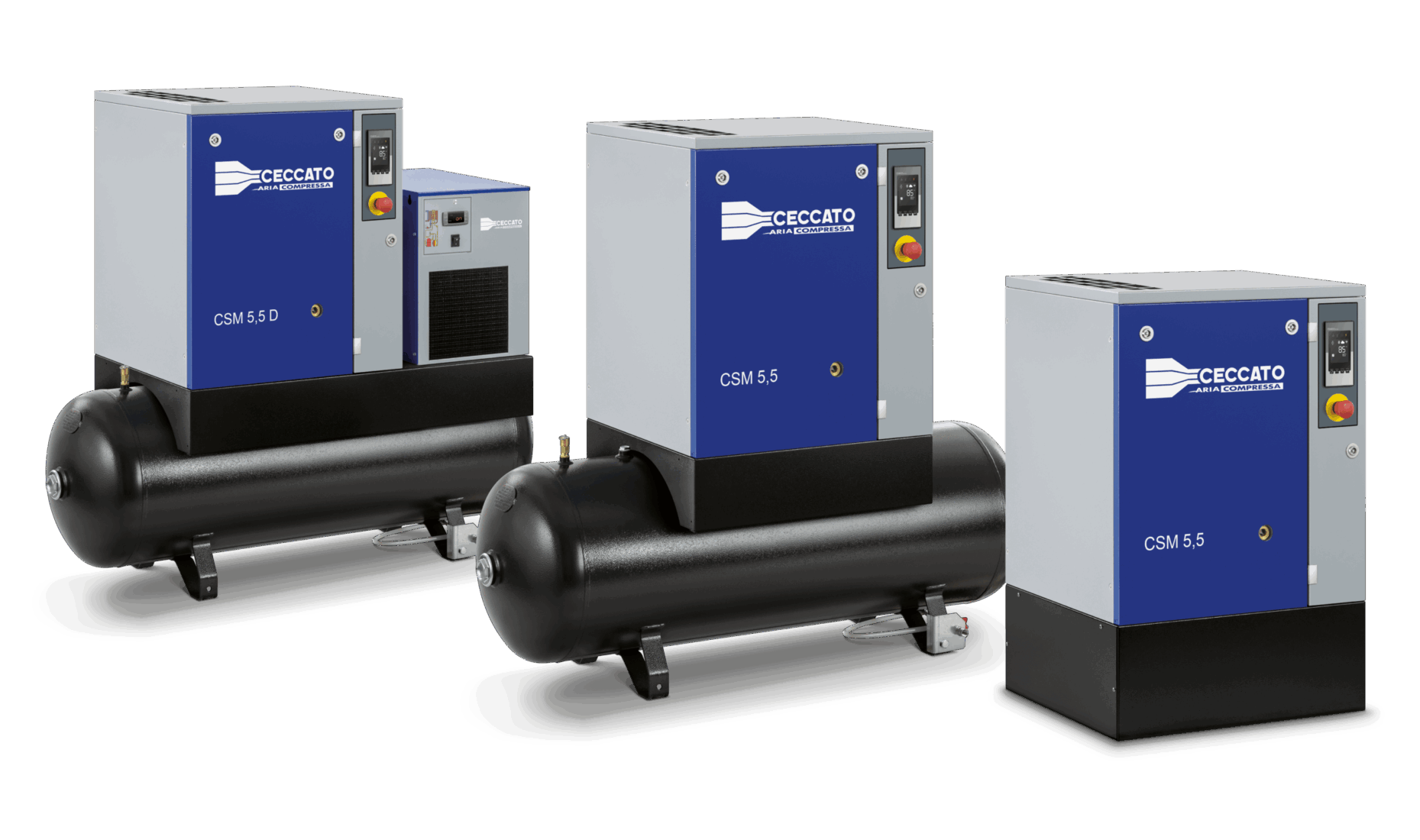

Rotary screw compressors offer comprehensive configuration flexibility to suit diverse workshop requirements. Base-mounted models provide maximum space efficiency for compact workshops, whilst tank-mounted configurations offer extended air storage capacity for applications requiring sustained high-volume air supply.

The compact design of rotary screw compressors maximises workshop floor space utilisation whilst delivering full industrial-grade performance. Easy access components simplify routine maintenance procedures, reducing downtime and ensuring rotary screw compressors maintain peak performance throughout their operational life.

Professional Support and Reliability

Choosing rotary screw compressors represents an investment in proven reliability backed by comprehensive professional support. Ceccato’s extensive service network ensures prompt assistance, genuine spare parts availability, and expert technical support that keeps your rotary screw compressors operating at optimal performance levels.

Rotary screw compressors combine advanced technology with robust construction designed for continuous workshop operation. For Australian professionals seeking the ultimate workshop compressor solution that delivers superior performance, energy efficiency, and long-term reliability, rotary screw compressors stand as the clear choice for enhanced workshop productivity and operational success.

Brochure: CSM 3-10 HP

Brochure: CSM 7.5-20 HP EN

Product Link: https: https://www.ceccato.com/en-international/air-compressor-products/rotary-screw-compressor/fixed-speed/csm-7-5-20-hp